Economical Good Price Duplex Paper Sheeting Machine, Roll to Sheet Cutting Paper Sheeter with CE

About ShengxiangRuian Shengxiang Packaging Machinery Co., Ltd. was established in 2010. It is a private economic entity

Basic Info.

| Model NO. | SX-SL1100 |

| Computerized | Computerized |

| Voltage | 380V 50 Hz |

| Total Power | 7 Kw |

| Cutting Precision | 0.2 mm |

| Motor | Jaskawa, Japan |

| PLA | Mitsubishi |

| Operation | Taiwan Touch Screen |

| Weight | 4000 Kg |

| Length of Cutting | 300-1000 mm |

| Cutting Width | 1100 mm |

| Speed | 30-150 Times/Min |

| Max Diameter of Material | 1400 mm |

| Keyword | Automatic Sheet Stacking |

| Max Stacking Heigh | 450 mm |

| Raw Material | Nonwoven Paper PVC Pet |

| Transport Package | Plastic Film Packing |

| Specification | 6000x1900x1400 mm |

| Trademark | Shengxiang |

| Origin | Zhejiang, China |

| HS Code | 8441100000 |

| Production Capacity | 20 Sets/ Month |

Product Description

About ShengxiangRuian Shengxiang Packaging Machinery Co., Ltd. was established in 2010. It is a private economic entity integrating development, design, production, sales, and service. Mainly specializing in the manufacture of packaging equipment such as cross-cutting machines, A4 paper cutting machines, slitting machines, roll paper cutting machines, rewinding machines, printing machines, and so on.Specification

| Model | SX-SL1100 | SX-SL1400 | SX-SL1600 |

| Cutting Width | 1100 mm | 1400 mm | 1600 mm |

| Max Diameter of Material | φ1000 mm | φ1000 mm | φ1000 mm |

| Length of Cutting | 300-1000 mm | 300-1000 mm | 300-1000 mm |

| Max Stacking Height | 420 mm | 420 mm | 420 mm |

| Thickness | 70-500 gsm | 70-500 gsm | 70-500 gsm |

| Cutting Speed | 10-120 times/min | 10-120 times/min | 10-120 times/min |

| Cutting Precision | ±0.2 mm | ±0.2 mm | ±0.2 mm |

| Total Power | 7 kw | 9 kw | 11 kw |

| Weight | 4000 kg | 4500 kg | 5000 kg |

| Overall Size (L x W x H) | 6000*1900*1400 mm | 6000*2300*1400 mm | 6000*2600*1400 mm |

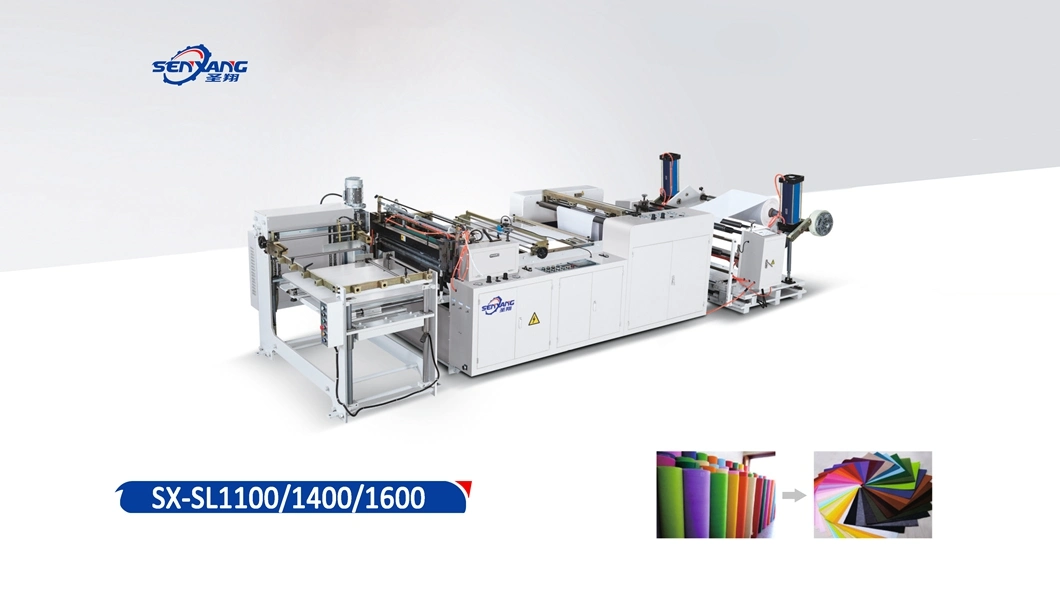

SX-SL1100/1400/1600 Automatic Stacking Crosscutting Machine

It adopts serve motor for controlling constant-length cutting. It adopts pneumatic, photoelectric sensor for controlling transmission system, with photocell, gas together. it has the functions of easy operation, high precision, good stability, low noise. (photo tracking function is optional.) this machine has the function of the frequency converter timing device, automatic counting, stop work by alarm magnet powder tension control, can be cutted vertically, adopts blower to get rid of waste.

Machine Details

Automatic Loading Unit 1. Pneumatic feeding system, suitable for your large roller material2. Automatic photocell EPC system | Magnetic Tension Control 1. Tension Magnet adopts 10KG/20kg controller, to keep your material flat and double side under same tension. |

Sheet Cutting 1. Heavy structure2. Imported balance front steel cutter | Auto Stacking, Max 420mm 1. Pneumatic lifting stack sheet table, automatic coming down with sheet collect.2. Each side with fixed or adjustable baffles to slip the finish |

Packaging Details

Why Choose Us - Shengxiang

1. Quality WarrantyOne Year Warranty We PromiseCommissioning services: Product arrived on site, Our Technical Staff Will Guide you to Finish installation,commissioning, andtraining How to operations Until you get it (Installation charge, buyer responsible)2. Training ServicesWe will provided a comprehensive technical training if necessary Training Include as following:(1) Normal operating procedures for equipment training.(2) Knowledge of routine maintenance on equipment training.(3) Introduction of the equipment and service solutions for training.3. Lifetime ServiceWarranty expires, we will provide life-long service to all customers on a regular basis to provide equipmentupgrades and maintenance services.4. Archives ServiceAfter execution of the contract, we will establishment of archives, including the sale contract, the technical parameters,commissioning acceptance of a single report, the relevant technical drawings.

ExhibitionCertification

FAQ1. Are you a factory or trading company?We are an actual factory and manufacturer with trading in the line of paper cutting machines, slitting machines for more than 10 years.2. Where is your factory located? How can I visit there?Our factory is located in Ruian City, Zhejiang Province, China,less than one hour by air from Shanghai. All our clients from home or abroad, are warming welcome to visit us!3. What about your payment term?For new customer, our payment terms is 30% T/T in advance before production, the balance 70% should be paid before delivery.4. Where is your main market?Our productts are sold well in 30 provinces and have good reputation in China, we pay attention to developing the overseas market, such as Europe, Russia, Southeast Asia, Middle and South America, Africa, and other countries all over the world.5. How dose your factory do regarding quality control?Quality is our soul of company. Our people always attach great importance to quality controlling from the very beginning to the very end. Our factory has passed CE certification. 6. What about warranty and do the engineers available to over seas?One year warranty. During this period, if some parts were problem, we will send by courier to you. 7. What about the after sales service?We provide the whole life after sales service. Even after one year warranty, we support the spare partts price without benefit.

Send to us