Sheeter for Paper and Board Cutting China Factory Hsc

Basic Info.

| Model NO. | HSC-1100, HSC-1400, HSC-1700, HSC-1900 |

| Type | High-Speed Slitting Machine |

| Work Method | Round Knife Cutting |

| Structure | Cutting Part |

| Packaging | Pallet |

| Classification | Rotary Paper Cutting Machine |

| Applicable Process | Process Materials |

| Suitable Substrates | Paper |

| Packaging Material | Wood |

| Knife Material | HSS |

| Paper Gram | 50-550GSM |

| Servo System | Inovance |

| Cutting Accuracy | +-0.3mm |

| PLC | Inovance |

| Roll Number | 1 Roll, 2 Rolls, 4 Rolls, 6 Rolls |

| Voltage | 380VAC, 50Hz, 3p or Customized |

| Cutting Paper Material | Coated Paper, Kraft Paper, Cardboard, Carton Paper |

| Max. Speed | 300 Cpm |

| Transport Package | Pallet |

| Specification | 1100 / 1400 / 1700 / 1900 |

| Trademark | HOUSENG |

| Origin | Made in China |

| HS Code | 84411000 |

| Production Capacity | 25 Per Month |

Packaging & Delivery

Package Size 1900.00cm * 490.00cm * 240.00cm Package Gross Weight 20000.000kgProduct Description

Product Description

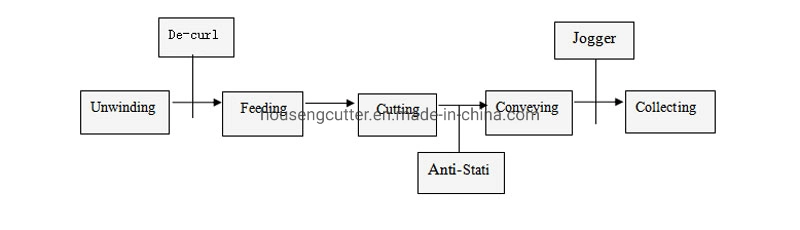

According to HOUSENG Product performance, the machine are mainly used for paper sheeting in Paper Mill, Printing House,Packaging and etc, mainly process including: Unwinding-Cutting-Conveying-Collecting .

1.Upper knife roller has the British cutter method to effectively reduce the load and noise during paper cutting, and to extend the life of the cutter. The upper knife roller is welded with stainless steel for precision machining, and is dynamically balanced during high-speed operation. Lower tool seat is made of cast iron integrally formed and cast, and then precision processed, with good stability

2.Touch screen controls are used to set and display sheet size, count, cut speed, delivery overlap, and more. The touch screen controls work in conjunction with a Siemens PLC.

3.Three sets of slitting knife unit to have a high speed, smooth and powerless trimming and slitting, with quick adjustment and locking. High rigidity knife holder is suitable for 300m/min high speed slitting .

Application:

Cutting reel (roll paper) into sheets

Technicals:

According to HOUSENG MACHINE, are mainly used for paper cutting in Paper Mill, Printing House and etc.

Mainly process including: Unwinding-Feeding-Cutting-Conveying-Collecting .

Our Advantages

Upper knife roll has the British cutter method to reduce the load and Rotary cutting knife is made of special alloy steel precision machining, | |

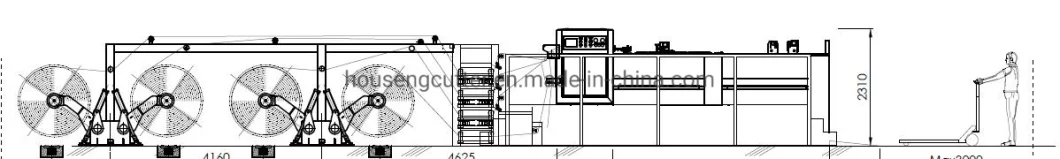

Dual position shaftless pivoting arm unwind stand 1)Max Reel Diameter: 1800mm | |

Slitting knife Three sets of slitting knife unit to have a high speed, | |

Motorized double decurler system Effectively remove the curl of the roll to make the paper more flat, | |

Delivery and Auto Jogger System Automatically goes down when paper piling up to a certain height. Conveyor system with mult-stage: | |

Electronic control INOVANCE Servo, INOVANCE PLC, Eaton, etc. | |

Delivery and Auto Jogger System The stacker table has three sides shake finishing function, | |

Transport department The fast/slow speed belt is controlled by the stepless frequency converter, | |

Auto counting and Automatic marking Type: Insert after counting precisely Auto -EPC (Edge Paper Control) Precision sensing nozzle which easily available and sensitive . Auto-tension control Put the paper roll diameter and paper weight number into touching screen, | Driving Motor system 1, AC Servo motor & encoder for cross knife |

Option Configuration

1. | Blade -Tungsten Steel |

2. | Cast Iron Main |

3. | Imports Of Electrical Appliances |

4. | Pneumatic slitting knife |

5. | Dust removal |

6. | Color code tracking system |

Main Technical Parameter

Model | HSC-1100 / 1400 / 1700 / 1900 |

Type of cutting | The up knife cut reciprocally and the down knife is fixed |

Paper weight range | 50-550 GSM |

Reel stand load capacity: | 2.5T (option 3T-4T) |

Reel diameter | Max 1800mm (71") |

Cutting Width | Max.1100/1400/1700/1900mm (66.9") |

Cut off length range | Min.400 / 450-Max. 1450 / 1650 mm |

Cutting accuracy | ±0.3mm |

Max. Speed of cutting | 300cuts/min |

Max. Cutting speed | 300meter/min |

Delivery height | 1500mm(incl.pallet) |

Voltage | AC380V/220Vx50Hz 3ph or customized |

Total power | 28kw |

Output | The real output depends on the material, and the weight of the paper, and right operate process |

Company Profile

ZHEJIANG HAOSHENG PRINTING MACHINERY CO.,LTD. HOUSENG is a leading company in china to produce sell sheet cutting machine /reel to sheet paper ,HOUSENG on extensive experience and fast develop speed in this field. Start from 2001, high performance models have evolved thanks to the commitment and know-how of our employees, intensive research and development, and the steady exchange with our customers on their needs and ideas .In the light of such policies as adapting to market demands ,basing on science and technology and seeking market share through quality ,HOUSENG aims to reduce cost and market competition ,provide better services for customer at home and abroad, and enable customers to obtain greater benefits. |