Basic Info.

| Model NO. | DCWQ-XE1800DR |

| Packaging | Case |

| Classification | Cloth Cutting Machine |

| Applicable Process | Process Materials |

| Suitable Substrates | Non Woven |

| Packaging Material | Wood |

| Min Slitting Width | 25mm |

| Weight of Machine | 12000kg |

| Slitting Speed | 0-400m/Min |

| Power Supply | 380V,50Hz,3pH |

| Transport Package | Wooden Case |

| Specification | 10000*4600*3200 |

| Trademark | TINUO |

| Origin | Zhejiang |

| HS Code | 8451500000 |

| Production Capacity | 500PCS/Year |

Product Description

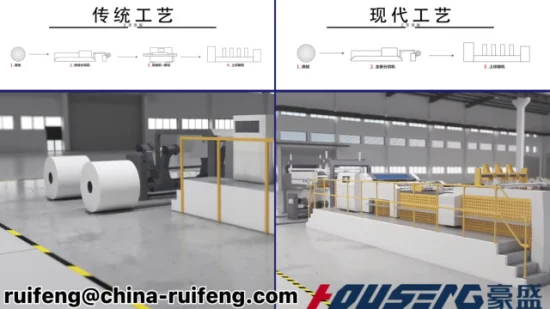

Double Rewinding Non Woven Slitting Machine1.Use:

The Machine suitable for many kinds of jumbo roll slitting. Such as 40-400g/m2 kraft paper,cardboard paper,corrugating paper,aluminum foil,plastic film,coated paper slitting &rewinding,special for paper bags,paper cups products industry.

2.Feature:1.Machine use PLC,three servo motor control, automatic tape tension, center and surface rewinding together.2.Machine use frequency converter adjust speed, keep stable running when speed up.3.Automatic count meter, auto alarm, it can automatic stop after it reached set meter on computer .4.Rewinding use Two pcs 3inch air shaft structure. Full automatic unloading finished rolls.5.Machine including Web Guide device(EPC) through sensor to control motor to move the edge. Guarantee unwinding feeding precision.6.Round knife slitting ,and waste edge of roll, and it's auto waste by fan .7.Shaftless automatic Hydraulic loading structure. Unwinding loading can be 5Ton Maximum3.Machine Technical Data:

| Technical parameter |

| Max width mother roll | 1600mm |

| Min width finished roll | 500mm |

| Max diameter mother roll | 1600mm |

| Max diameter finished roll | 1300mm |

| Max mother roll weight | 5000KG |

| Speed of slitting | 0-400/min |

| Slitting capability | 40-400gsm |

| Rewinding way | Central&surface |

| Precision | ±0.2mm |

| Speed regulation control | Frequency converter |

| Power input | 380V,50HZ,3PH |

| Total power | 55KW |

| Dimension | 10000*4600*3200 |

| Total weight | 12000KG |

| Drive system |

| Main motor | 18.5KW,Servo motor |

| Rewind motor | 18.5KW,Servo motor(2sets) |

| Feeding roller | Rubber roller |

| Transmit roller | Aluminum roller |

| Transmit way | Synchronous |

| Pressing way | cylinder |

| Rewinding shaft | Pneumatic shaft |

| Bearing | Renben |

| Slitting equipment |

| Slitting way | Blade knife slitting |

| Blade knife | 5sets |

| Adjustment way | Freely by manual |

| Unwinding equipment |

| Unwinding type | Shaft-less ,hydraulic heavy type |

| Lifting way | Hydraulic control |

| Unloading type | Automatic unloading |

| Guide way | Right&Left 75mm |

| Unwinding equipment |

| Unwinding type | Shaft-less ,hydraulic heavy type |

| Lifting way | Hydraulic control |

| Unloading type | Automatic unloading |

| Guide way | Right&Left 75mm |