High Speed Hobbing Cutter Automatic Jumbo Paper Roll Sheeter China Factory

Hob Cutter type servo-driven paper roll to sheet cutting machine-Two rolls(reels) Feeding Technical Information Field pu

Basic Info.

| Model NO. | HQ-H1400 |

| Warranty Period | 1 Year |

| Max.Diameter of Roll | 1650mm |

| Material | Paper |

| Max.Cutting Length | 1600mm |

| Weight | 11000kgs |

| Certification | CE |

| Power | 25kw |

| Voltage | 1/2/3 Phase, 220/380V, 50Hz |

| Transport Package | Wooden Box |

| Specification | 12000*3900*2300mm |

| Trademark | SNDA, OEM |

| Origin | Wenzhou, China |

| HS Code | 8441100000 |

| Production Capacity | 10 Sets Per Month |

Product Description

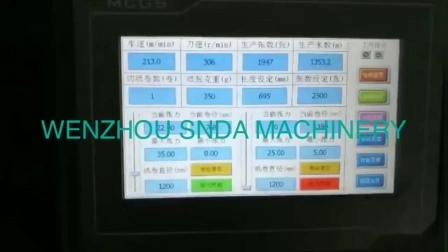

Hob Cutter type servo-driven paper roll to sheet cutting machine-Two rolls(reels) Feeding| Model | HQ-H1400 | HQ-H1700 |

| Reference weight of cutting paper | 50-500g/m2 | 50-500g/m2 |

| Max.Diameter of paper | 1650mm(65")Max | 1650mm(65")Max |

| Max.Width of paper | 1400mm(55")Max | 1700mm(67")Max |

| Total power | 25KW | 28KW |

| Cutting length | 400-1600mm | 400-1600mm |

| Cutting accuracy | +/-0.4mm | +/-0.4mm |

| Maximum cutting speed | 300cuts/min | 300cuts/min |

| Maximum cutting meter speed | 300m/min | 300m/min |

| Atmospheric pressure | 0.8MPa | 0.8MPa |

| Power supply | AC380V/220Vx50HZ | AC380V/220Vx50HZ |

| Total weight | 11000kg | 13000kg |

| Dimensions | 12m×3.9m×2.35m | 12m×4.2m×2.35m |

Technical Information

Field public facilities

1. Compressed air to the maximum pressure80psi(3KW,0.8MPA);

2. AC power supply for three-phase380V,50Hz;DC power supply24V,AC; 3. Pressure regulator:380V / 50KW;

4. Cable:16mm²(three-phase line);

5. Ground load demand:2000kg/m²

6. Equipment operating environment temperature between 5 degrees Celsius to 40 degrees Celsius;

Automatic Roll Unwinding Unit

Automatic Roll Unwinding Unit is Equipped with Hydraulic Shaftless Roll Stands two clamps and Braking system, which are Easy-to-use During Roll Manipulations

Prevent curling system

Adjusting the roll paper due to the curl of the paper, make the paper smooth after cutting.

Knife holder and Cutting blade

A total of two knives, one fixed on the base ,the other is on the holder for rolling cutting.

Send to us