Full Automatic Guillotine Sheeter Paper Roll to Sheet Cross Cutting Machine Gw1700

Full Automatic Sheeter Paper Roll to Sheet Cross Cutting Machine for Kraft Paper/Paperboard/Grey Paper/Craft Paper GW170

Basic Info.

| Model NO. | GW1700-6 |

| Computerized | Computerized |

| Max. Paper-Cutting Width | 1700mm |

| Gross Weight | 20000kgs |

| Range of Cutting Length | 450-1670mm |

| Max. Paper Roll Diameter | 1800mm |

| Cutting Type | Single Rotary Sheeter |

| Transport Package | Wooden Case |

| Specification | Dimensions: 21200*3920*2300mm |

| Trademark | GUOWEI |

| Origin | China |

| HS Code | 84411000 |

| Production Capacity | 1000 Sets/Year |

Product Description

Full Automatic Sheeter Paper Roll to Sheet Cross Cutting Machine for Kraft Paper/Paperboard/Grey Paper/Craft Paper GW1700-6Product Description:

Servo Precision High Speed Sheet Cutter apply the advanced imported technique. The

servo motor ,AC transducer ,the conveyor belt and pneumatic vibrator apply international brand;the electrical system adopts SCHNEIDE & OMRON to make the cutting speed fast and stable. Germany precise bearing and cutting knife assure the high cutting precision.

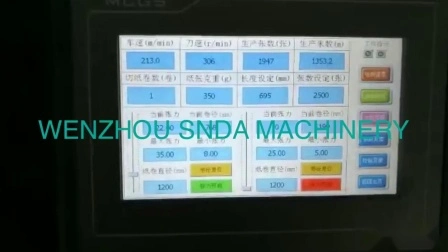

The touching screen makes the operation easy. The anti-curve rack assure the paper flat. This machine is the paper processing machine which is very popular in the paper making and printing industry. It can improve the efficiency and benefit of your work.

| Model | GW1700-6 |

| Cutting type | Single rotary sheeter |

| Applicable range of paper | 45-550g/ |

| Max. paper roll diameter | 1800mm |

| Max. paper-cutting width | 1700mm |

| Range of cutting length | 450-1670mm |

| Cutting sheet number | 2 sheet |

| Cutting precision | (Cutting length) ≤1000mm: 0.5mm |

| Max. cutting speed | 300 cut/min |

| Max. feeding speed | 300 m/min |

| Max. paper stacking height | 1500mm |

| Air pressure source requirement | 0.8Mpa |

| Power | 380V*50HZ |

| Gross weight | 20000KGS |

| Full-load power | 34kw |

| Dimensions | 21200×4200×2300mm |

1,Imported AC servo and PLC control system are adopted to make the cutting speed of the machine faster, more accurate and more stable2,10-inch touch screen with self-diagnosis function, making operation simple and convenient3,With recurve structure to make the paper flat and smooth4,This machine is suitable for a wide range of applications, such as cardboard, coated paper, kraft paper, cultural paper, double-coated paper, gold and silver cardboard, tobacco and alcohol packaging paper, aluminum foil paper, laser laser paper, etc.

Product Advantage Technology:

Internet of Things: It can dynamically track, realize the synchronization between the management background computer or mobile phone and the machine screen, monitor the technical parameters such as the running speed of the machine and the number of paper sheets in real time, record information such as early warning and alarm, and realize remote program update and upgrade, as well as remote guidance. Machine maintenance.

Adopt Imported Electric compents such as Panasonic,Inovance and Idec

Floating aluminum roller deviation correction device

Adopt sun wheel paper delivery device and rubber roller to press paper.

Equipped with high-precision spiral device and alloy steel blade

The conveyor belt adopts Chinese, Japanese and other brands

Our Advantages :

Experience in paper cutting machine for over 30 years and served customers all over the world. Enjoying high reputation in domestic & oversea market. We have biggest production, 80%of our cutting machines are for export, so our machine is following closely to quality.

A group of High-tech technical staffCooperating with famous group, such as: Schneide r, OMRON, MOELLER, LG, Leuze electronic, AirTAC, ABB, NSK, Mitsubishi, Panasonic, atos, brevini etc. Our commitment Strictly follow ISO quality control, competitive price, fast deliveryWe will not take a chance on selling marginal or poorly made products. Remeber we are ZHEJIANG GUOWEI PRINTING MACHINERY Co., Ltd, We are strive to achieve quality best, service best! You are welcome to purchase our equipment!

QC Team:

More than 10 persons to check the machine's quality, every machine need 1 week to make adjustment, ensure 100% qualitative product.

Shipment:

We will keep tracking with the container until clients receive it. 40HQ, 40GP, 20FT(LCL, FCL)

CREATE VALUE FOR CUSTOMER IS OUR TARGET! CONTACT US NOW!

Send to us