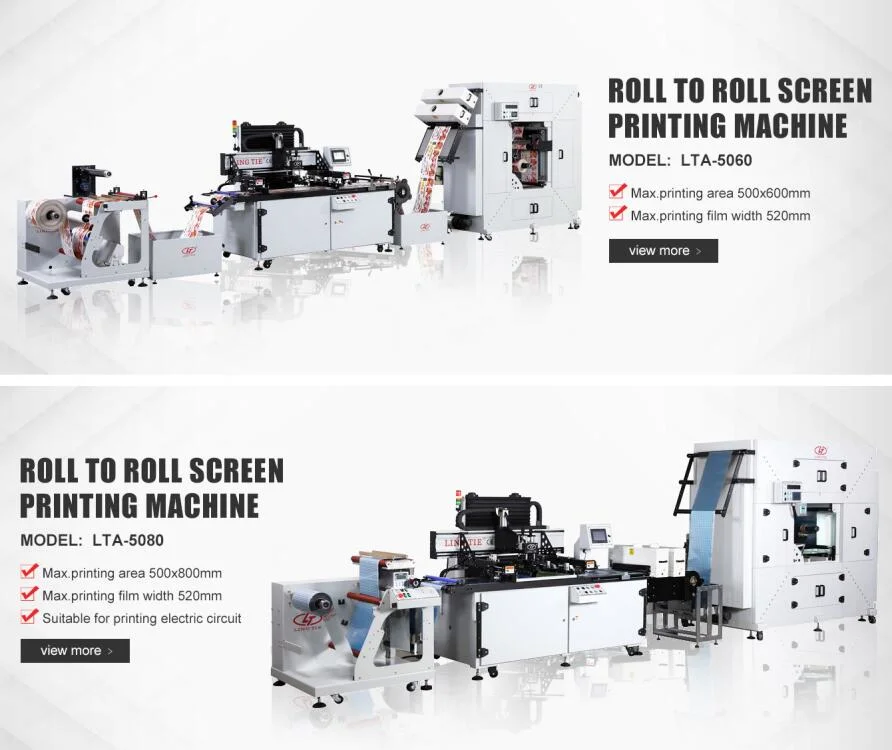

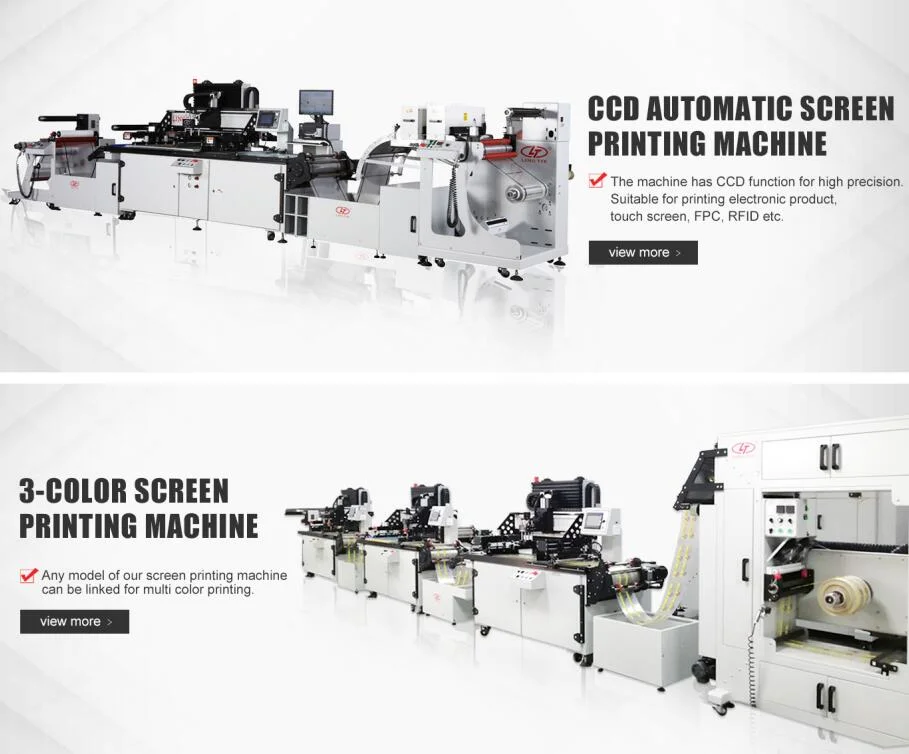

Automatic Roll to Roll Silk Screen Printing Machine for Nameplate Panel, FPC, IMD, Frid, Heat Transfer Label

Basic Info.

| Model NO. | LTA-3040 |

| Max Printing Size | (300X400)mm |

| Raw Material Types | Pet, PVC, PE, PV, PP, PC, BOPP, Adhesive Stickers |

| After-Sales Service Provided | Engineers Available to Service Machinery Overseas |

| Registration Accuracy | +/- 0.01mm |

| Certification | CE and ISO9001:2015 |

| Transport Package | Wooden Box |

| Specification | (L7000xW1100xH1900)mm |

| Trademark | LINGTIE |

| Origin | Xiamen, China |

| HS Code | 8443911900 |

| Production Capacity | 30sets/Mouth |

Product Description

Automatic Roll to Roll Silk Screen Printing Machine

Machine Description:

The Automatic Roll to Roll Silk Screen Printing Machine is designed to print on film material in roll, such as PET, PVC, PE, PV, PP film.

This screen printing machine is composed of a feeder, a printing unit and a hot air dryer.

The feeder has dust removal rollers, it is able to alarm when the roll material run out.

The printing unit table has vaccum to fix PET film in position to ensure printing accuracy. It is equipped with three photocell sensors for automatic registration.

The hot air dryer has 30M, 60M and 80M length pass for option. It is able to cool and wind cured film into a roll after being dried.

High level of automation, only one people can operator the the whole printing line.

High printing accuracy, multi color overprint can be done on the machine.

High productivity, production capacity equal to six sets of semi-automatic screen printing machine.

Automatic roll to roll silk screen printing machine includes a feeder, a screen printing unit and a hot air dryer.

Application: RFID, heat transfer label, labels and stickers, membrane switches, graphic overlay, IMD, IML, FPC, ceramic decals, motorcycle helmet decals, nameplate and non-woven fabrics, etc.

Machine Parameters:

| Model | LTA-3040 | LTA-5060 | LTA-6080 | |||||

| Max. Printing Size | 300x400mm | 500x600mm | 600x800mm | |||||

| Printing Speed | 0~5000 print/hr. | 0~2500 print/hr. | 0~2500 print/hr. | |||||

| Max. Screen Frame Size | 600x800mm | 800x1000mm | 900x1200mm | |||||

| Frame Adjusting Variable | 60mm | 60mm | 60mm | |||||

| Max. Substrate Width | 320mm | 520mm | 620mm | |||||

| Registration Accuracy | ±0.01mm | ±0.01mm | ±0.01mm | |||||

| Air Source | 0.4~0.6mpa | 0.4~0.6mpa | 0.4~0.6mpa | |||||

| Power | 220V, 3KW, 15A | 220V, 3KW, 15A | 220V, 3KW, 15A | |||||

| Printing Material Thickness | 0.02~0.5mm | 0.02~0.5mm | 0.02~0.5mm | |||||

| Weight | 600kgs | 700kgs | 950kgs | |||||

| Overall Dimensions (L*W*H) | 7000x1100x1900mm | 8100x1360x2260mm | 9000x1350x2200mm | |||||

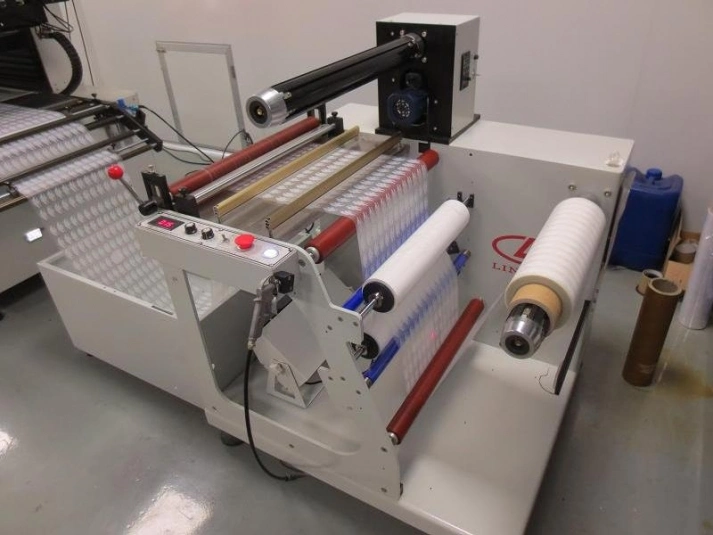

Machine Photos:

Vacuum table: fix the PET film during printing process. Automatic register system for screen alignment.

feeder: dust removing, protect film removing, electrostatic eliminating,etc.

Print Head: Good stability, ensure long time use of the machine.

Hot Air Dryer: 30m, 60m, 80m inner loop hot air dryer for optional.