Yaojia Yjc

Basic Info.

| Model NO. | YJC-1200 |

| Power Supply | 380 Volts 3 Phase 50 Hz |

| Compressed Air | 6 Bar |

| Electrical Connected Load | 26kw |

| Bearings | NSK Japan |

| Belts | Nitta Japan |

| Air Tank Capacity | 60 L |

| Air Compressor Capacity | 10 M3/H |

| Processed Materials | Cardboard 200~800 GSM, Corrugated E-Flute and F-F |

| Min Feeder Size | 86mm*60mm |

| Machine Weight | 8.5 Ton |

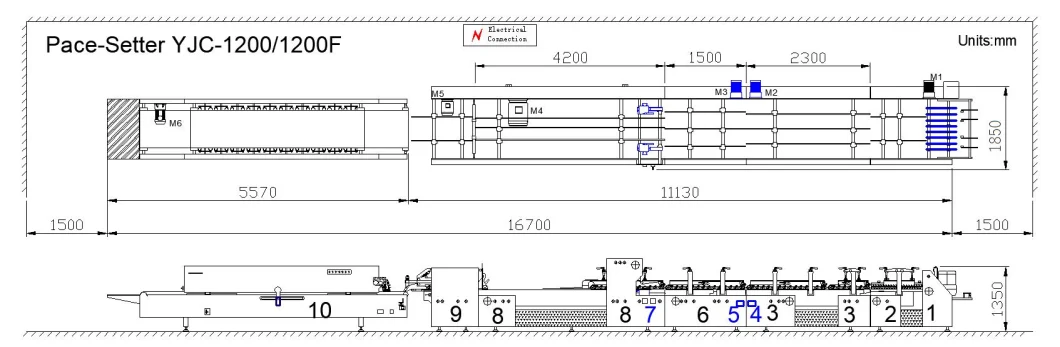

| Machine Dimensions | 16.7m*1.85m*1.8m |

| Model | Yjc-1200 |

| Max Feeder Size | 1250mm*1000mm |

| Max Speed | 400m/Min |

| Transport Package | Pallets |

| Specification | Max Feeder Width: 1250mm |

| Trademark | YAOJIA |

| Origin | China |

| HS Code | 8441309000 |

| Production Capacity | 30sets/Month |

Product Description

Product Description

Product Parameters

| Processed Materials | |

| Cardboard | 200~800 gsm |

| Corrugated Flute Type | E-flute and F-flute |

| Capability | |

| Speed | Max. 400 m/min |

| Paper Width Size | Max. 1250 mm, Min. 86 mm |

| Dimensions & Weight | |

| Length | 16.7 m |

| Width | 1.85 m |

| Height | 1.8 m |

| Net Weight | 8.5 Ton |

| Installation | |

| Electrical Connected Load | 26 KW |

| Power Supply | 380 Volts 3 Phase 50 Hz |

| Compressed Air | 6 bar |

| Air Compressor Capacity | 10 m³/h |

| Air Tank Capacity | 60 L |

Installation Instructions

Machine Details

Feeder

- Fully Automatic Feeder With Servo Motor 5kw

- 8 pcs 30mm Friction Belts Soft Rubber Compound (optional extra 4 vacuum belts)

- 4 Back Carton Supports

- 3 Front paper supports (Quick adjustment for thickness of substrate)

- 2 Paper Side Guides

- Vibrator

- Full Colour Video Monitor (Supervise view final product at the end of the Machine)

- 2 Bottom Transport Carriers (fitted with 34mm wide Belts)

- 1 left Hand Side Squaring Guide

- 1 Right Hand Side Squaring Guide

- 4 Top paper support guides

- Adjustable top Carriers fitted with independent lever system which can be independently applied giving the desired pressure required for the alignment of Substrate carton blank

- Electronic movements of carriers in and out of working position (Via remote control)

- 1st and 3rd crease

- Bottom left had side carriage 43 millimeter wide belt

- 3 Bottom Carriers

- 3 Top carriers

- Electronic movements of carriers in and out of working position (Via remote control)

- 3 Bottom Transport carriers

- 3 Top Transport carriers

- Bottom chromed support bars

- Electronic movements of carriers in and out of working position (Via remote control)

- 2 Servo Drive Motors 2kw Each

- 3 Folding Hooks 4 Corners

- 3 Folding Hooks 6 Corners

- 6 Corner Box Lid Can Be Folded from the Left or Right hand side Of Machine

- Moveable Touch screen Commander Module (For programing Measurement's: Speed and position and Electronic angel of the folding Hooks)

- Folding 2 and 4 crease

- Equipped with 2 glue tanks 1 Left 1 Right with 4 M/m disc

- Guide rollers Left and right

- Adjustable speed control of belts left and right

- Electronic movements of carriers in and out of working position (Via remote control)

- Double Trombone (Telescopic)

- Independently motor drive

- Electronic movements of carriers in and out of working position (Via remote control)

- Motorized variable speed control of Belt Speed for smooth delivery

- Moveable Touch screen Commander Module

- 1 Drive Motor

- Front and Backward position

- Pneumatic pressing (Adjustable via Pneumatic Regulator valves)

- Squaring Device

Detailed Photos

Company Profile

YAOJIA Machinery is a professional Folder Gluer manufacturer in folding carton packaging industry. The company has developed a complete supply chain from R&D, assembly to pre-sale consulting, and sales as well as after-sales service. With rich technology and capital resource, we pay high attention to the innovative design. Every year we have at least one new design machine to satisfy our customers'demand.

The products are sold all over in China and exported to more than 30 countries and regions such as Europe, Southeast Asia, South America, Middle East and Africa.

Creating value for customers first is the only way to achieve self-worth. We look forward to cooperating with you!

Packaging & Shipping

FAQ

1

Q:What is the machine warranty? A:one year.2

Q:Does your machine with CE certificate? A:Yes.3

Q:What is the production time while placing order? A:About 30~45 days after get the payment.4

Q:Can your company handle shipping for customers? A:Yes.(Please provide us your requested seaport and we can check the shipping charge and arrange shipping for your order)5

Q:Does the packing strong? A:Yes, of course! Packing is with steel pallets, suitable for long-distance road and vessel transportation and various types of weather conditions.6

Q:How do I order spare parts? A: Have the machine model and serial number (nameplate). In your parts manual, have the page number, item number, and parts description. Belts, for example, come in many different widths, lengths, and thickness. Having all the above information ensures the correct item is ordered.7

Q:Are you manufacturer? A:Yes, we are manufacturer. YAOJIA focus on folder gluer machine. I would like to bring you to visit us and look inside the machine details, to trace machines' original manufacturing processes, and to know the people behind the machines.8

Q:Do you have stock product to sell? A:Actually our machine need 30 days to manufacture, and there are many orders from China and foreign countries, so we need custom one for you, and your order will be highly attention to manufacture.

9

Q:Do you inspect the finished products? A:Yes, we have QC department, they will inspection the machine before shipping, to ensure there is nothing problem of the machine .10

Q:What's the payment term? A:T/T 30% in advance, the balance paid before delivery.